What is the best material for building furniture for the nautical furnishing market?

This is the question posed by a large supplier and distributor of composite materials.

Maricell promptly answered the question, performing a series of specific tests on different core materials.

The ideal characteristics for creating nautical furnishings have always been: lightness, unity with the maximum achievable strength. The weak point in the realizations of this sector is the screw-material junction. Understanding which material can withstand a greater load can answer the initial question in the first instance.

Maricell has conducted tests according to the DIN EN 320 standard (determination of resistance to axial withdrawal of screws) in its research and development laboratories.

The tests were aimed at measuring and comparing the values of maximum tolerable strength in the screw / material joints in the various materials under investigation, namely PET and expanded PVC .

How were the tests conducted?

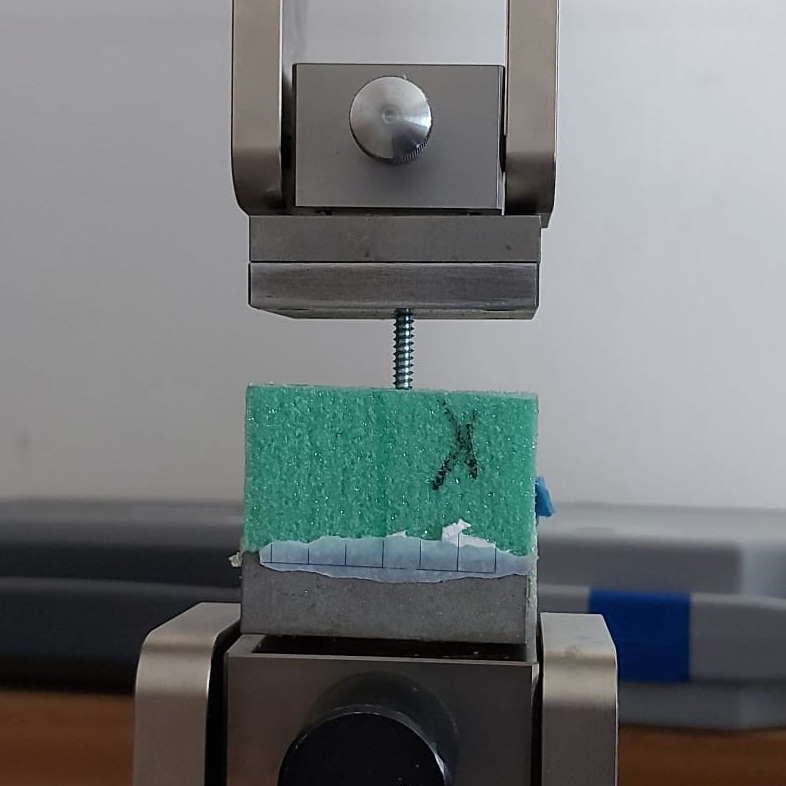

It is basically a TRACTION test

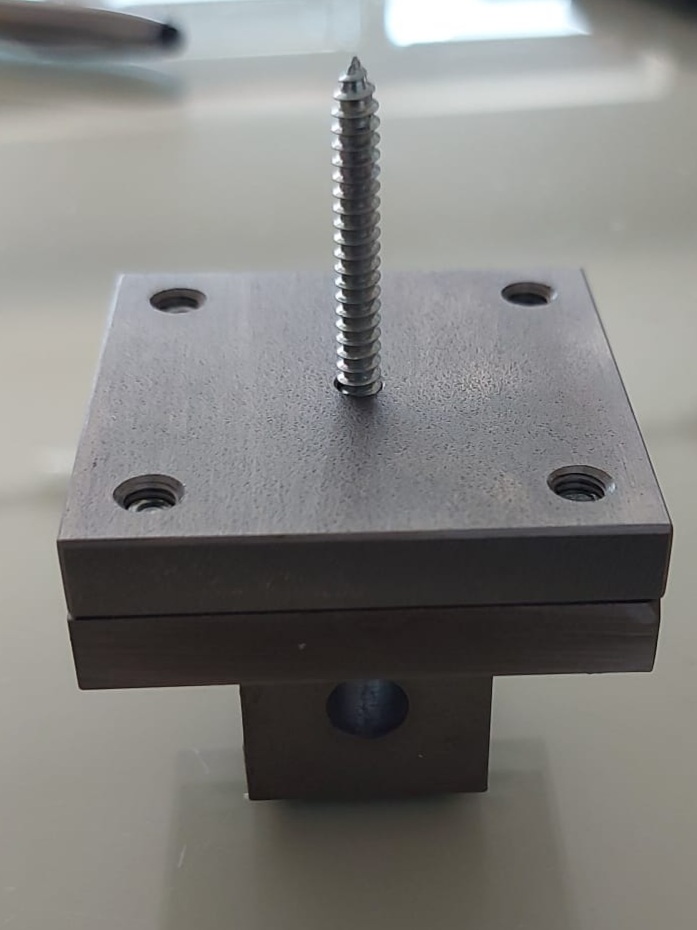

The screw is screwed into a specimen of certain dimensions for a depth of 15mm.

A tensile test is then carried out with a dynamometer and the maximum holding force of the screw in the material is measured.

For both materials, different densities were considered: 130, 200 and 250 Kg / m3

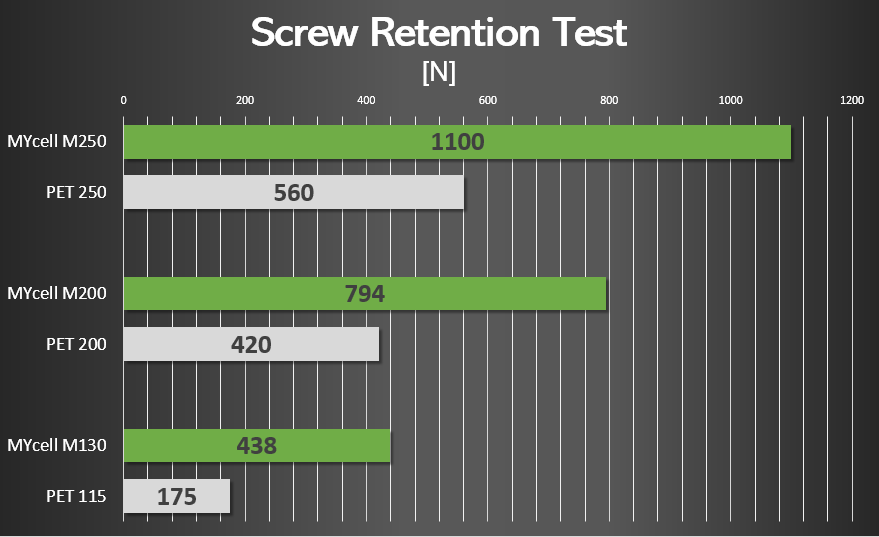

Test result:

The result that emerged clear: it can be concluded that Maricell's PVC is practically twice as resistant as competitive PET .

MYcell in the variants M130, M200 and M250 they proved to be a excellent material for the realization of furniture in the nautical sector

The values that emerged from the test are easily comparable in the graph below.